According to the Association of State Dam Safety Officials, the current average age of the 90,580 dams in the country is 56 years. Recently, dam safety has garnered increasing attention due to a high number of failures, including several that gained national media coverage. From January 2005 to June 2013, the U.S. State Dam Safety Program reported 173 dam failures. Additionally, there were 587 occurrences that, without intervention, would likely have resulted in dam failure. As time continues, these dams are growing older and the number of deficient dams is climbing. Dam facility inspection is becoming ever important to reduce failures that may cause loss of human life, economic loss, and/or environmental damage.

A Safer, Faster (and Yes, Cooler) Alternative

The use of unmanned aerial systems (UAS) – or "drones" – offers a rapidly emerging solution to help dam and reservoir owners manage and protect their facilities. UAS equipped with high-resolution cameras and sensors provide safer and more efficient tools than traditional methods for inspecting and monitoring dam and levee structures.

Oftentimes, dam facilities have large-scale structures that are time-consuming to inspect and require special safety equipment and procedures to physically access. Dam inspectors often measure by hand, which takes time, can be costly, and increases safety risks; especially when rope access teams are needed for inspections of concrete dam structures. UAS technology can be used rather than humans for these often-hazardous inspections or for examinations of inaccessible features.

Benefits of UAS (Drone) Inspections

- Speed – UAS can capture high-quality imagery and data in a short period. Once onsite, the actual field flight time varies from a few minutes to a few hours depending on facility size and data being collected, instead of a full day or multiple days.

- Agility – UAS can assist with emergency inspections or in areas that are dangerous or difficult to access. Multirotor UAS can hover and hold a position while the operator moves the camera to focus on interest points or zooms to investigate potential concern areas.

- Safety – UAS provide a safe method to inspect a dam or facility by keeping the operator away from hazardous areas. The collected data can be evaluated from a live feed in the operator’s handheld device or after the flight, away from the hazard.

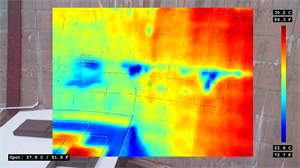

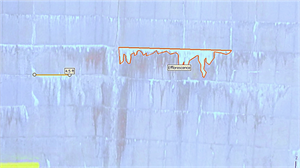

- Deliverables – UAS can be outfitted with multiple sensors such as high-definition video, thermal-infrared, multispectral, LiDAR, and others. Collection of data with different sensors provides the operator the ability to evaluate a dam with more than just visual inspection. The most typical data collected with UAS includes photos and video; however, multiple data products can be generated.

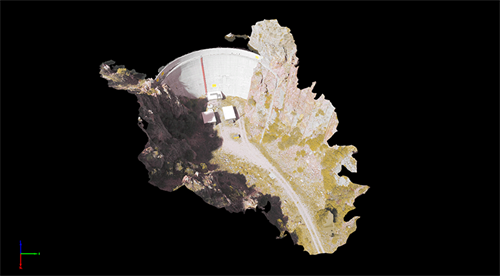

- Using photogrammetry software, overlapping photos can be used to generate 3D point clouds and terrain models for analysis and design. Additionally, the photos can be combined and scaled to fit the terrain, creating seamless, spatially-accurate aerial images for use in CAD and GIS applications.

- Aerial images can also be overlaid on 3D terrain models, creating a high-resolution 3D environment that can be inspected and analyzed virtually. Thermal and multispectral imagery can also be overlaid on the model to assist with analysis and documentation.

- Cost savings – Rope or crane access inspections are often expensive and, if undertaken correctly, require significant time to set-up, test, and move locations. They also require appropriate permits and safety approvals. UAS can significantly reduce field time by decreasing mobilization costs and allowing more efficient use of staff resources.

When to Use UAS

Our UAS professionals have conducted over 1,000 flights and mapped more than 30,000 acres using UAS technology. Our dam and reservoir projects have benefited from UAS applications, including:

- Volumetric Surveying

- Topographic Mapping

- Structure Condition Assessment

- Change Detection

- Flood Hazard Mapping

- Vegetation Assessment and Monitoring

- Cultural Resources/Archaeological Documentation

A Few Things to Keep in Mind

Although UAS are cost-effective and efficient inspection tools, there are items to consider before flying, including:

- Federal Aviation Administration (FAA) flight rules and restrictions - The FAA has strict rules for operating UAS. Additional FAA approvals are often required and take time in advance to acquire.

- Site authorizations – Many land owners and agencies require specialized UAS permits to operate near or over their facilities. This may vary from a simple site permit to a full UAS program audit.

- Accuracy requirements – The data is only valuable if it provides the accuracy required for the project and is technically defensible. Detailed workflows and quality control procedures are foundational for producing engineering or scientific data products.

- Flight planning strategies – Planning a project for the appropriate aircraft, sensor, speed, altitude, and data resolution is critical to obtaining the data quality needed for inspection and design applications.

- Site conditions and weather – UAS performance and data quality can be impacted by site conductions such as dust from vehicles, smoke from fires or flares, or vapors from cooling or process equipment. Such site and environmental conditions need to be considered when scoping a project and can significantly impact both data quality and cost. Additionally, wind, rain, snow, sun, and cloud cover can impact data quality and need to be evaluated during the planning process.

- Handling and processing large amounts of geospatial data – The data generated from UAS sensors is highly detailed and data rich, but that means significant amounts of data. Depending on the sensor, a typical flight can easily generate 5-10 gigabytes of raw data. During data processing, that dataset can expand as much as 10 times. Understanding how to process, share, store, and utilize big data is key to successfully implementing UAS technology.

Trihydro’s staff includes licensed Part 107 pilots who can safely and legally perform commercial aerial data acquisition. Additionally, data is processed in-house by our team of licensed surveyors, engineers, and geospatial professionals. Get a feel for the power of UAS by watching the video below.

WATCH DEMO VIDEO >

Contact our team with questions or for more information:

Daniel Mummert, P.E.

Unmanned Systems Program Specialist

(830) 626-3588

[email protected]